French Fries CUTTING AND GRADING

After destoning, washing, and peeling, the next step in French fries production is cutting and grading the potatoes. Let’s explore these processes: Cutting:

French Fries COOLING AND FREEZING

After frying, French fries undergo cooling and freezing processes to preserve their quality, extend shelf life, and facilitate distribution. Here’s a breakdown of these essential steps in French fries production: Cooling:

French Fries BLANCHING

Blanching is a critical step in French fries production that involves partially cooking the cut potatoes before they are fried. This process helps to achieve the desired texture, color, and flavor of the final French fries. Here’s a closer look at blanching in French fries production: Purpose of Blanching: Process of Blanching:

Production Cost Calculation Consultancy

Production cost calculation consultancy services are vital for businesses across various industries, providing expertise in accurately assessing the costs associated with manufacturing processes and products. Here’s an overview of the key aspects and services typically offered by production cost calculation consultants: Cost Analysis and Assessment:

Food technology Consultancy

Food technology consultancy encompasses a broad spectrum of services aimed at assisting food businesses, manufacturers, and entrepreneurs in various aspects of food production, processing, safety, and innovation. Here’s an overview of the key areas and services typically offered by food technology consultants: Product Development and Innovation: Food Safety and Quality Assurance: Regulatory Compliance and Certification: […]

Food Production Technical Consultancy

Food production technical consultancy services offer expert guidance and support to food manufacturers, processors, and other stakeholders in the food industry. These services encompass a wide range of areas, including production processes, quality control, food safety, regulatory compliance, product development, and efficiency improvement. Here’s an overview of what food production technical consultancy entails: Production Processes […]

Food industry Initial feasibility study

A feasibility study is a crucial step in assessing the viability of a food industry project, whether it’s launching a new product, establishing a new manufacturing facility, or expanding an existing operation. Here’s an outline of the key components typically included in an initial feasibility study for a food industry project: Executive Summary: Introduction: Market […]

Tortilla chips baking machines

BAFI® for equipment for tortilla chips production, including baking machines, are essential for ensuring the efficient and high-quality manufacturing of this popular snack. Baking machines are pivotal in the tortilla chip production process as they cook the chips to perfection, achieving the desired texture, crispiness, and flavour without the need for deep frying. Let’s explore […]

Stackable potato Stacking machines

BAFI® for equipment for stackable potato chip production lines are essential for ensuring efficient and high-quality manufacturing of this popular snack. Stacking machines are pivotal components within these production lines, responsible for arranging the cooked potato chips into neat stacks, ready for packaging and distribution. Let’s explore the significance and offerings of stacking machines provided […]

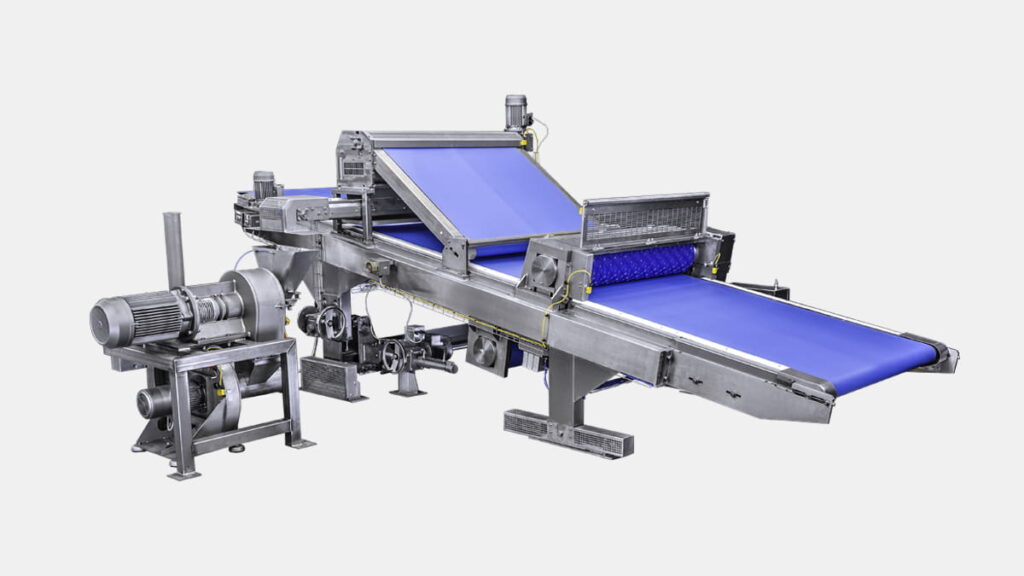

Stackable potato Sheeting machines

BAFI® for equipment for stackable potato chip production lines play a crucial role in ensuring efficient and high-quality manufacturing of this popular snack. Sheeting machines are essential components within these production lines, responsible for shaping and forming the potato chip mixture into uniform sheets before the cutting process. Let’s explore the significance and offerings of […]